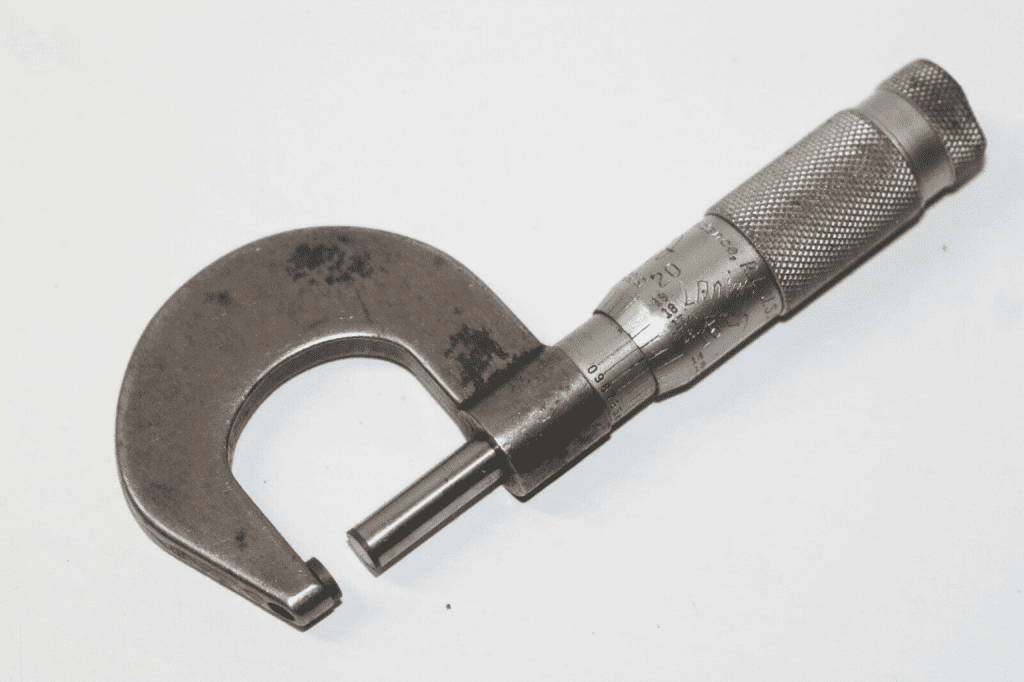

The micrometer, often referred to as a micrometer screw gauge, stands as one of the most iconic tools in precision engineering. Its development revolutionized the way small dimensions were measured, providing machinists and engineers with unprecedented accuracy. With origins dating back to the early 19th century, this seemingly simple instrument became essential across industries requiring meticulous standards. Let’s delve into the history, usage, and enduring legacy of the vintage micrometer.

Origins of the Micrometer: A 19th-Century Innovation

The story of the micrometer begins with French inventor Jean Laurent Rixens, who patented the first micrometer in 1829. During this period, accurate measurements of tiny objects were a significant challenge. Existing tools lacked the precision required for emerging industrial needs. Rixens’ invention filled this gap, quickly gaining popularity for its ability to measure small dimensions with remarkable accuracy.

The initial design was rudimentary by today’s standards, but it laid the foundation for future improvements. The micrometer was first adopted by machinists and engineers in fields like manufacturing and mechanical engineering. In these industries, the need to ensure the precise fit of components was critical for quality control. As technology advanced, so did the micrometer’s design, becoming an indispensable tool for professionals working with high tolerances.

The Evolution of the Micrometer Design

Following Rixens’ invention, the micrometer saw significant advancements over the years. One of the most notable improvements was the addition of the vernier scale, which allowed for even more precise measurements. With this modification, machinists could measure down to fractions of a millimeter or thousandths of an inch, depending on the model.

Additionally, the materials used in micrometer construction improved significantly. Early versions were prone to wear and tear, but later models incorporated hardened steel and other durable materials. These changes enhanced both the accuracy and longevity of the tool, making it a long-term investment for professionals.

How a Micrometer Works: The Principle Behind Precision

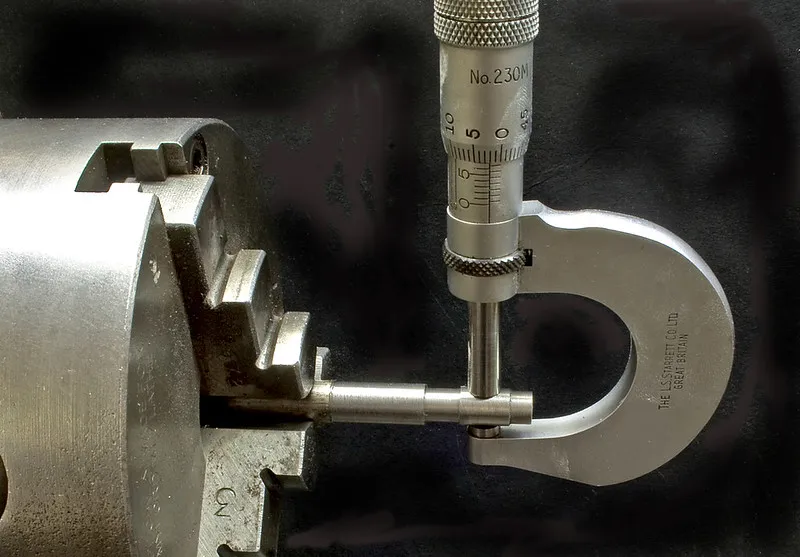

The micrometer operates on a simple but effective principle: a screw mechanism that allows for fine adjustments and highly accurate measurements. Typically, the tool consists of three main components: a calibrated screw, a movable spindle, and an anvil. The object to be measured is placed between the spindle and the anvil, and as the screw is turned, the spindle moves closer to or further from the anvil, compressing the object.

The beauty of the micrometer lies in its ability to measure with extreme precision. By turning the screw a small amount, the machinist can measure distances as tiny as one micrometer (one millionth of a meter) or one mil (one thousandth of an inch). This level of precision is essential in industries like aerospace, automotive, and precision engineering, where even the smallest discrepancies can lead to costly errors.

Applications of the Micrometer in Modern Industries

While the micrometer has evolved over time, its primary purpose remains unchanged: to provide highly accurate measurements for small objects and surfaces. In today’s world, micrometers are used in a wide range of industries:

- Aerospace: Engineers use micrometers to measure parts with extreme accuracy, ensuring that all components fit perfectly and function as intended.

- Automotive: From engine parts to braking systems, the automotive industry relies on micrometers to guarantee the precision of each component.

- Manufacturing: Quality control is paramount in manufacturing, and micrometers help ensure that products meet exacting standards before they reach the consumer.

- Medical Devices: In fields like prosthetics and medical equipment, accurate measurements can mean the difference between life and death.

Despite the emergence of digital and electronic measuring devices, the classic vintage micrometer continues to be used by craftsmen who appreciate its tactile precision and mechanical reliability.

The Legacy of the Vintage Micrometer

Before digital tools became commonplace, the micrometer was the epitome of precision measurement. It played a pivotal role in ensuring quality and reliability in industries that demanded perfection. The tool allowed machinists to achieve tolerances previously thought impossible, driving advancements in manufacturing, engineering, and even scientific research.

Today, vintage micrometers have become collector’s items, prized for their intricate design and historical significance. Enthusiasts appreciate the craftsmanship involved in their creation, as well as the impact they had on the technological development of the 19th and 20th centuries. Many of these tools are displayed in museums and private collections, showcasing the innovation and ingenuity of early mechanical engineering.

For those who still use them in workshops or personal projects, vintage micrometers offer a tangible connection to the past. They represent an era when precision was achieved through craftsmanship and mechanical prowess, long before the convenience of digital readouts and automated machines.

The Transition to Modern Digital Micrometers

While the classic vintage micrometer remains an icon of mechanical precision, the modern world has seen the rise of digital micrometers. These newer tools offer the same level of accuracy as their mechanical predecessors but with added convenience. Digital readouts eliminate the need to manually interpret measurements from the micrometer’s scale, reducing the margin for human error.

Additionally, digital micrometers can store data and even connect to computers for further analysis, making them ideal for high-tech industries and quality control labs. However, despite their advantages, many professionals still prefer the tactile feedback and simplicity of the vintage micrometer, particularly in situations where reliability is key.

Conclusion: The Enduring Importance of the Micrometer

The history of the micrometer is one of innovation, precision, and craftsmanship. From its humble beginnings as a screw gauge in the 19th century, this tool has played a central role in advancing industries that demand meticulous accuracy. Whether in a machinist’s toolbox or a museum display, the vintage micrometer remains a symbol of precision engineering at its finest.

Even in today’s digital age, where electronic devices dominate, the micrometer’s legacy endures. Its contribution to the world of measurement and mechanical design is irreplaceable, and it serves as a reminder of the ingenuity and dedication that shaped modern technology. As long as there are industries that require exact measurements, the micrometer — in both its vintage and modern forms — will continue to hold a place of prominence.