Dovetail jigs have become an essential tool in the world of woodworking, known for their precision in creating sturdy, aesthetically pleasing joints. Whether you’re a novice woodworker or a seasoned professional, dovetail jigs offer a streamlined way to achieve high-quality results. This article explores the history, applications, and lasting legacy of dovetail jigs, showcasing their impact on modern woodworking.

A Brief History of Dovetail Jigs

The origins of the dovetail joint can be traced back thousands of years to ancient Egypt and China, where artisans crafted furniture and structures using intricate joinery. The dovetail joint gained popularity due to its strength and ability to resist being pulled apart, making it a preferred method for building durable structures. However, creating these joints by hand was a labor-intensive process that required years of skill and practice.

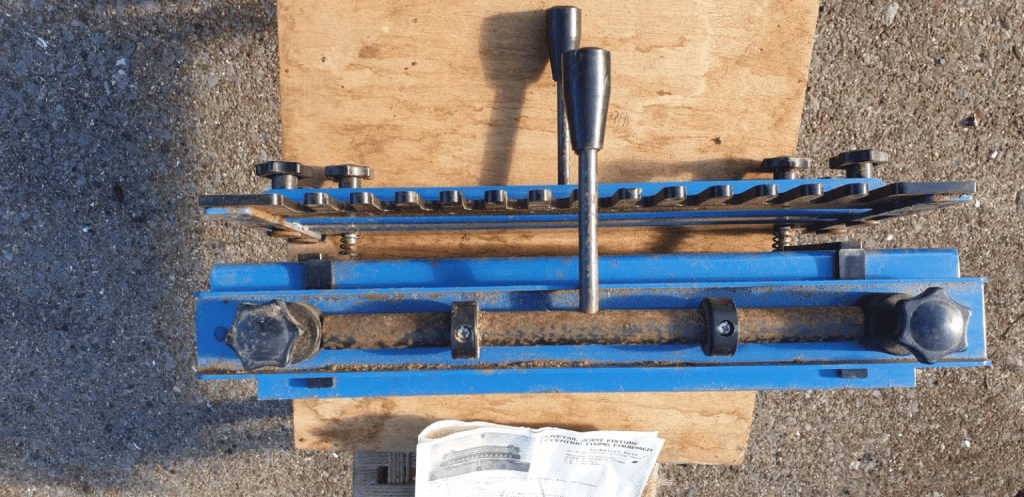

It wasn’t until the late 20th century that dovetail jigs became widely available, revolutionizing woodworking. Initially crafted from metal, these tools allowed woodworkers to create perfect dovetail joints without the need for extensive training. By using templates and guides, dovetail jigs simplified the process of cutting the necessary angles, making it accessible to a wider audience and elevating the quality of projects across the board.

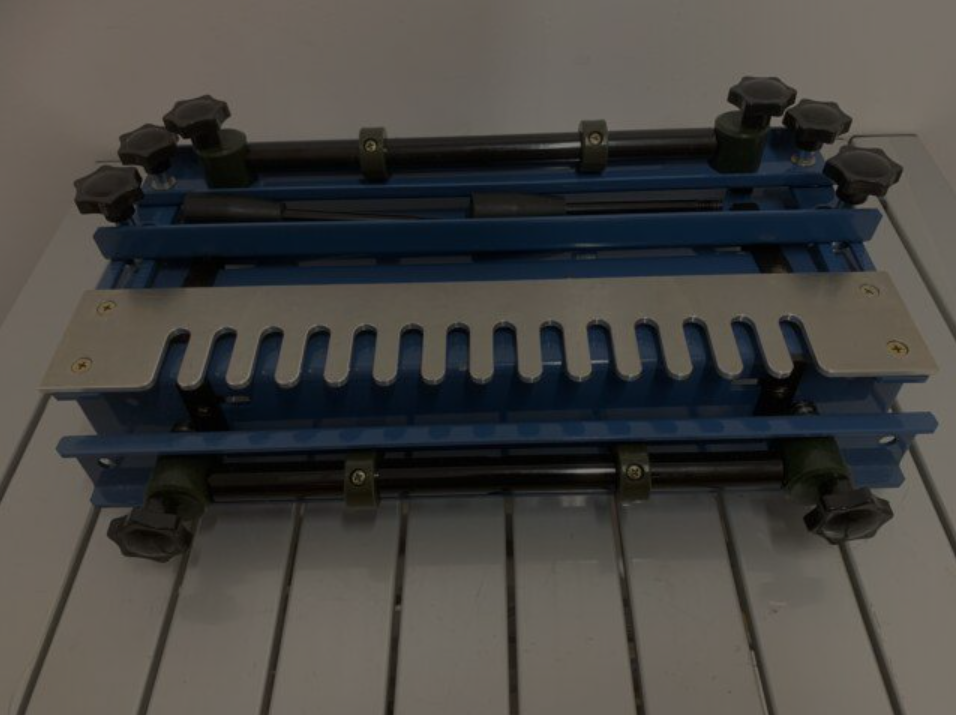

How Dovetail Jigs Work: The Modern Approach

A dovetail jig works by holding the wood securely in place while guiding the user in making precise cuts, typically using a router or saw. This eliminates the guesswork and human error that often occurs when attempting to cut dovetails by hand. The jig can be adjusted to accommodate different wood thicknesses and joint types, including:

- Through dovetails: Both sides of the joint are visible, showcasing the interlocking pins and tails.

- Half-blind dovetails: Only one side of the joint is visible, commonly used in drawer fronts.

- Sliding dovetails: A hybrid joint that combines elements of both strength and aesthetics, often used in cabinetry.

By simply adjusting the jig and securing the wood, users can repeatedly cut joints with exact precision, making it ideal for both one-off projects and mass production.

Practical Applications of Dovetail Jigs

Dovetail jigs are incredibly versatile and are used across a wide range of woodworking projects. Here are some of the most common applications:

1. Furniture Making Dovetail joints are often found in high-quality furniture due to their strength and beauty. From drawers to cabinets, dovetail jigs ensure that joints fit tightly and hold up under stress. For woodworkers aiming for durability and longevity, dovetail joints are a go-to method.

2. Cabinetry Cabinet makers often rely on dovetail jigs to create seamless, secure joints that enhance the overall aesthetic of their pieces. The strength of dovetail joints makes them ideal for cabinet doors and drawers, which endure frequent use over time.

3. Hobbyist Woodworking Projects For DIY enthusiasts and hobbyists, dovetail jigs offer a way to elevate their craftsmanship without requiring years of experience. Whether building small boxes, chests, or shelves, dovetail jigs allow hobbyists to achieve professional results with ease.

The Evolution of Dovetail Jigs: From Tradition to Innovation

While the basic concept of dovetail joinery remains the same, the tools and methods have evolved dramatically over time. Modern dovetail jigs incorporate advanced materials like aluminum and carbon fiber, making them lighter and more durable. Additionally, some jigs now feature micro-adjustment capabilities, allowing woodworkers to fine-tune their cuts for unparalleled accuracy.

Another innovation in dovetail jigs is the integration of CNC (Computer Numerical Control) technology. This allows for automated cutting, enabling mass production of intricate dovetail joints with minimal human intervention. Despite these advancements, the essence of dovetail jigs remains unchanged—they continue to simplify a complex woodworking technique while delivering exceptional results.

Why Dovetail Joints Are the Gold Standard in Woodworking

What makes dovetail joints so popular among woodworkers? The answer lies in their inherent strength and visual appeal. The interlocking design of the joint distributes stress evenly, making it less likely to fail over time. Additionally, dovetail joints create a decorative pattern that is often left visible in high-end furniture pieces.

In woodworking circles, mastering the dovetail joint is often seen as a rite of passage. With the introduction of dovetail jigs, this mastery is now achievable for a wider range of individuals, from hobbyists to professional craftsmen.

Cultural Impact: Dovetail Jigs in Woodworking Communities

Dovetail jigs have not only made a significant impact on individual projects but have also played a role in shaping woodworking culture. These tools are frequently used in woodworking classes, tutorials, and workshops, where aspiring craftsmen learn the importance of precision and attention to detail. Additionally, dovetail jigs have empowered DIY enthusiasts to take on more ambitious projects, contributing to the growing trend of handmade, artisanal furniture.

Woodworking competitions and exhibitions often highlight the use of dovetail joints as a mark of quality craftsmanship. The ability to create intricate, flawless joints with a dovetail jig has become a badge of honor in the woodworking community, further solidifying the tool’s cultural significance.

Dovetail Jigs: A Lasting Legacy in Woodworking

The legacy of dovetail jigs extends beyond the workshop. These tools have democratized woodworking, making it possible for individuals without years of training to produce professional-grade pieces. Whether you’re crafting a simple drawer or an elaborate piece of furniture, dovetail jigs provide the precision and reliability necessary to bring your vision to life.

As woodworking continues to evolve with new technologies and techniques, the dovetail jig remains a timeless tool that embodies both tradition and innovation. Its role in fostering craftsmanship and quality in woodworking is undeniable, and its presence in workshops worldwide is a testament to its lasting value.

Conclusion: Why Every Woodworker Should Own a Dovetail Jig

Dovetail jigs are more than just tools—they represent the intersection of art and engineering in woodworking. By offering precision, ease of use, and versatility, dovetail jigs enable woodworkers of all skill levels to create strong, aesthetically pleasing joints with confidence. Whether you’re a seasoned craftsman or a beginner looking to take your projects to the next level, a dovetail jig is an invaluable addition to your toolkit.

In conclusion, if you’re serious about woodworking, investing in a high-quality dovetail jig will not only improve the durability and beauty of your projects but also enhance your overall craftsmanship.